Our Capabilities

A complete range of vacuum forming and manufacturing solutions, all under one roof.

Always looking for new innovative techniques and machinery, we continuously improve our quality and service to customers.

The staff of ACRON Plastics have around forty years of industry experience manufacturing custom vacuum formed products for many diverse industries, including food/beverage, retail, marine, technology, healthcare, agriculture and a number of products for O.E.M. and industrial applications.

Vacuum Forming and Thermoforming experts

ACRON Plastics are the expert provider of custom plastics vacuum forming manufacturing services to a diverse range of industries, New Zealand wide.

The Vacuum Forming Process

Thermoforming, the forming of plastic sheet with heat and pressure (or vacuum) to force the hot sheet against a mould face, is the fabrication method for most plastic formed into useful end products. It is suitable for smaller production runs, where Injection Moulding is not economically viable.

Vacuum forming is a simplified version of thermoforming. Plastic is heated to a forming temperature, stretched onto a single-surface frame, and forced against the mould by a vacuum. This process can be used to form plastic into permanent objects such as turnpike signs and protective covers. It is a simple process that produces resilient, lightweight, and seamless parts quickly and efficiently.

The benefits of thermoplastic vacuum forming

There are several advantages of thermoplastic vacuum forming, which include:

- Significantly reduced tooling, machine time and material costs - the tooling is less complicated and lower loads making this process more economical to use for production than injection moulding. Moreover, a production run can be set up with several moulds on the same machine bed, to form multiple impressions reducing machine time and material costs.

- More extensive material choice – depending on the time and budget and finish required, production tools or moulds can be made from epoxy or polyester resin, cast aluminium, milled aluminium or wood – see our full list of materials here.

- Suitable for a wide range of products and components – the versatile nature of vacuum forming means it works well for a wide range of industries, from bespoke industrial design companies to those requiring more standardised components.

- Sustainable plastic solution - ACRON Plastics works hard to minimise our impact on the environment. All plastic waste produced in the forming process is granulated and sent back to plastic manufacturers to be recycled and extruded back into a plastic sheet.

Our Vacuum Forming and Pressure equipment

ACRON Plastics are always looking for new innovative techniques and machinery to improve our quality and service to our customers. The quality products we present to customers are in part a reflection of our carefully selected mechanism. We use top of the line vacuum forming equipment such as 5 x ILLIG vacuum forming machines and Thermwood 5 axis CNC router to allow us to manufacture products accurately no matter its size.

CNC MACHINING AND TRIMMING

ACRON Plastics has its own in-house CNC machines, capable of putting your idea into your hands quickly, efficiently and cost-effectively.

- We have state-of-the-art full 5-axis and 3-axis CNC trimming capability for products ranging from small intricate shapes and designs to larger formings up to 3.5m x 2.5m x 1.0m in height.

- Our machinery accepts DNC programming that allows rapid development of plastic prototypes and production parts.

- Our CNC trimming machinery can accommodate double skin assemblies with wall thicknesses over 12mm.

- Each of our trimming machines is specified to focus on production efficiency and output with custom design machine layouts.

- Specialises in plastics machining including 3d programming and 3d mould machining

At ACRON Plastics, we machine patterns, tools & trim plastic components quickly, efficiently and cost-effectively. Contact us today to discuss your specific requirements.

fabrication and assembly

ACRON Plastics provides fabrication and assembly services for products employing many auxiliary plastic fabrication services that are often required to pull your product together, from the thermoformed plastics to finished product. The typical processes involved include ultrasonic welding, heat bending, gluing, drilling, using a clicker press and diamond or flame polishing. These processes typically consist of adding hardware, machined or fabricated metal or plastic parts, and electronics to the thermoformed parts to create the final product. Sometimes manifold vacuum thermoformed parts are bonded to form a single assembly or outsourced sheet metal or machined plastic parts are added to provide upper-level assemblies.

Our FULL CAPABILITIES:

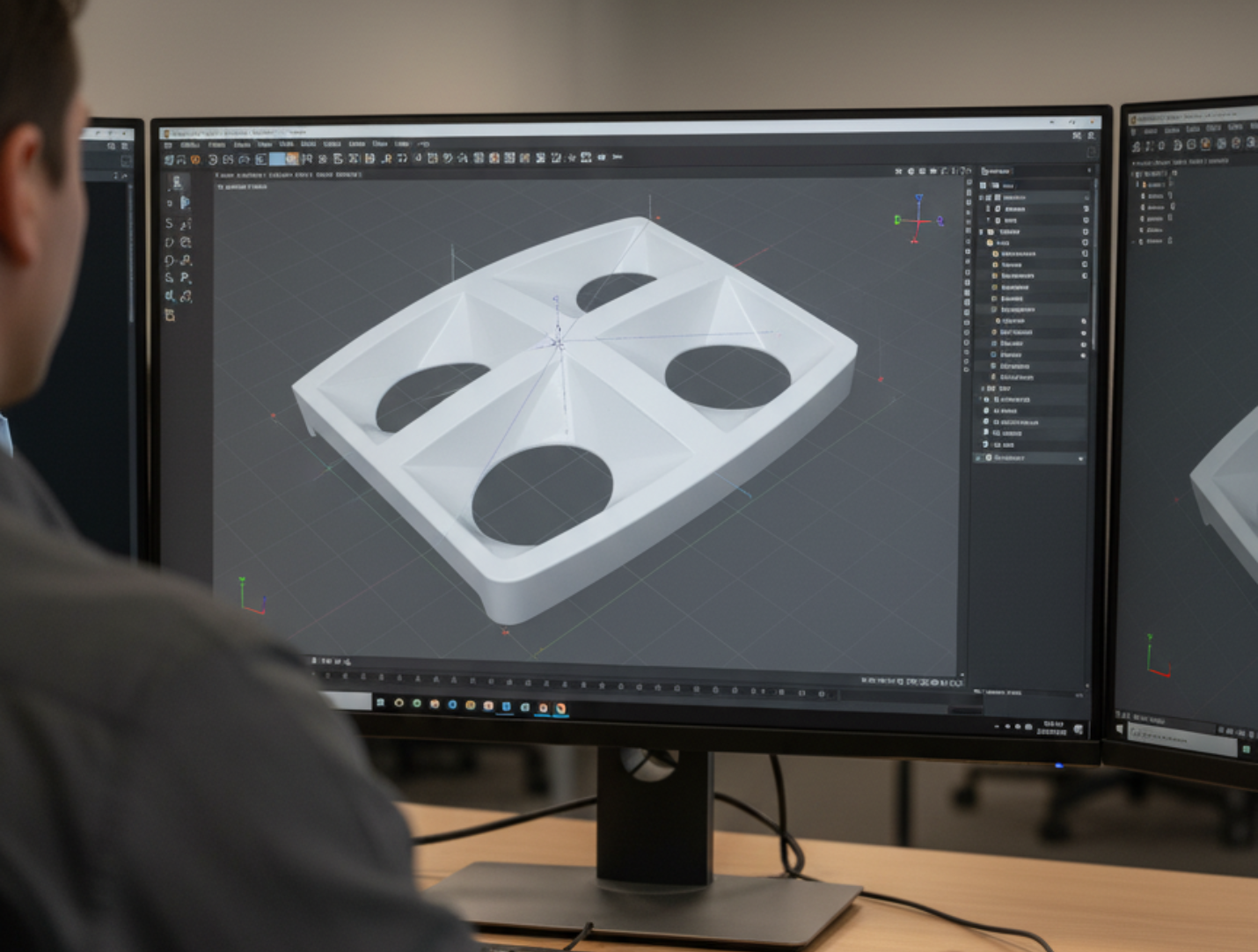

ACRON Plastics Limited offers turnkey new product design or a flexible extension of your in-house team. From conception to design to production, we provide value at every step.

We create products that exceed user expectations about performance, quality, and cost. It may also need to meet stringent regulatory requirements.

Our expert team will help design and transform your product vision to life, working closely with you and your team to brainstorm, develop concepts, and discover the best product design solutions.

Product Design

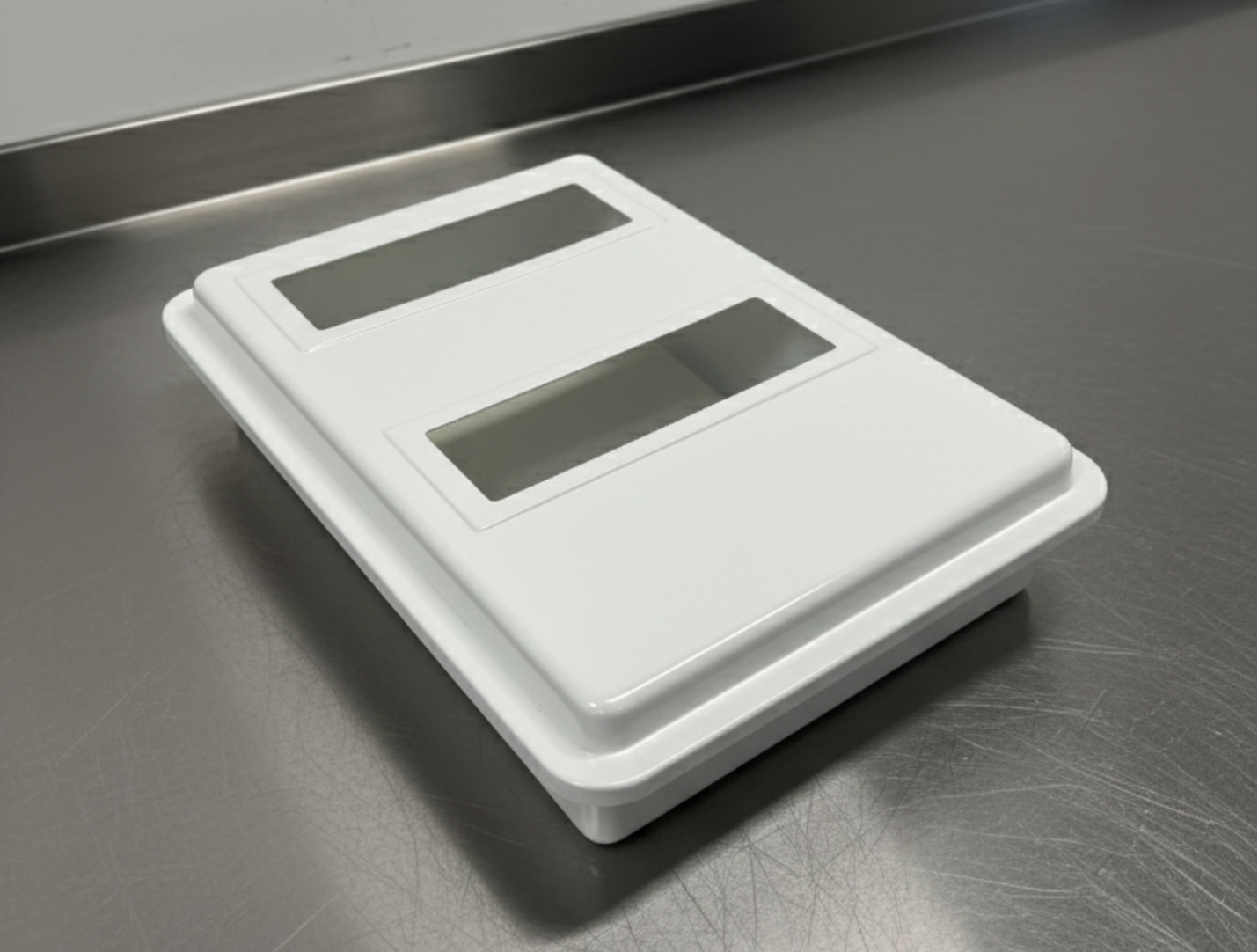

Vacuum forming can be used for projects like:

Product packaging

Optics packs and containers

Totes, guards, housing and other machine part applications

Medical applications

We work with you in developing a part or adapting your product design to accommodate our process. Prototypes can even be produced, without destroying your budget. Let’s get started. Talk to us about your next project.

As a value-added service, ACRON Plastics make it easy for customers to complete their products and get these products to market more quickly, while reducing the need and cost to coordinate

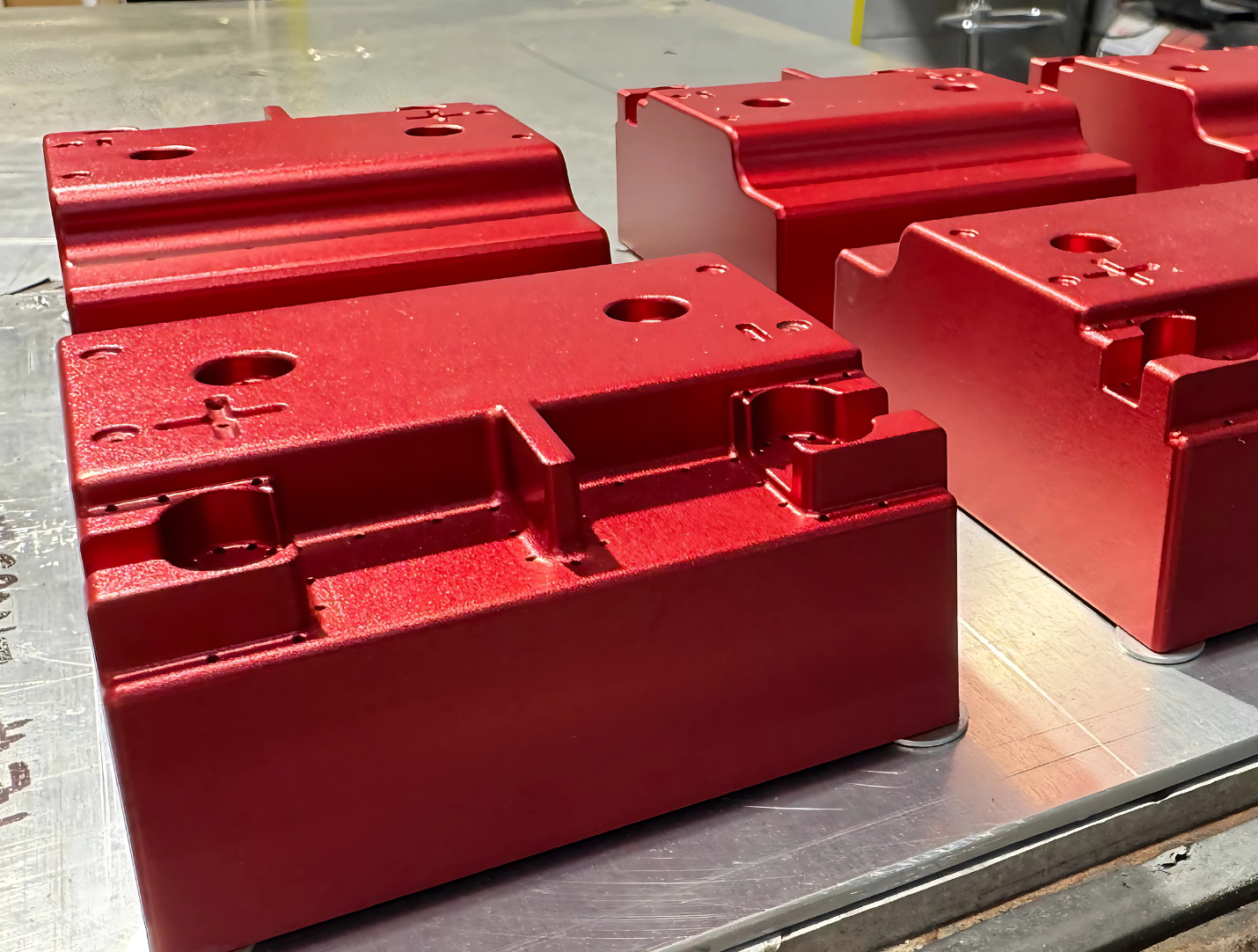

Tooling

A wide range of markets are served within the plastic processing sectors including tooling for:

- Vacuum Forming Tools Cast/Machined

- Injection Mould Tools - Specialists in Alum Tooling

- Structural Foam Tools

- Reaction Injection Moulding

- Blow Mould Tools

- Compression Mould Tools

- EPS Tooling

We produce moulds both from castings and machined from solid, or a combination of both. At ACRON Plastics Limited, our skilled toolmakers utilise the latest Computer-Aided Manufacturing software to output CNC data direct from your computer-aided design model. Our CAD and CAM facility enables us to work with designers and processors to achieve the best result in every project handled. Additionally, the moulds are produced both from castings and machined from solid, or a combination of both.

We work closely with clients to ensure any technical issues are resolved before manufacture the tooling thus providing a smooth transition from concept to production.

Retail Displays

Plastics vacuum forming is the process of heating a sheet of plastic until it’s pliable enough to conform to a mould of any shape. This manufacturing method is ideal when you want dynamic, multidimensional acrylic displays that are sure to attract customers’ attention. ACRON Plastics offer the most innovative thermoforming technology on the market, so you can rest assured that your displays are made to your exact specifications.

We work with a wide range of materials including acrylic and HIPS which are available in a wide range of colours.

We can also include your logo and graphics on display with our modern vinyl cutting machine. We can deliver excellent store displays in metal or wood in conjunction with plastic parts. No matter how elaborate or straightforward your POP displays, store displays, or retail displays are, our custom vacuum forming will produce the sharpest details and textures. Contact us today to begin the design and fabrication process.

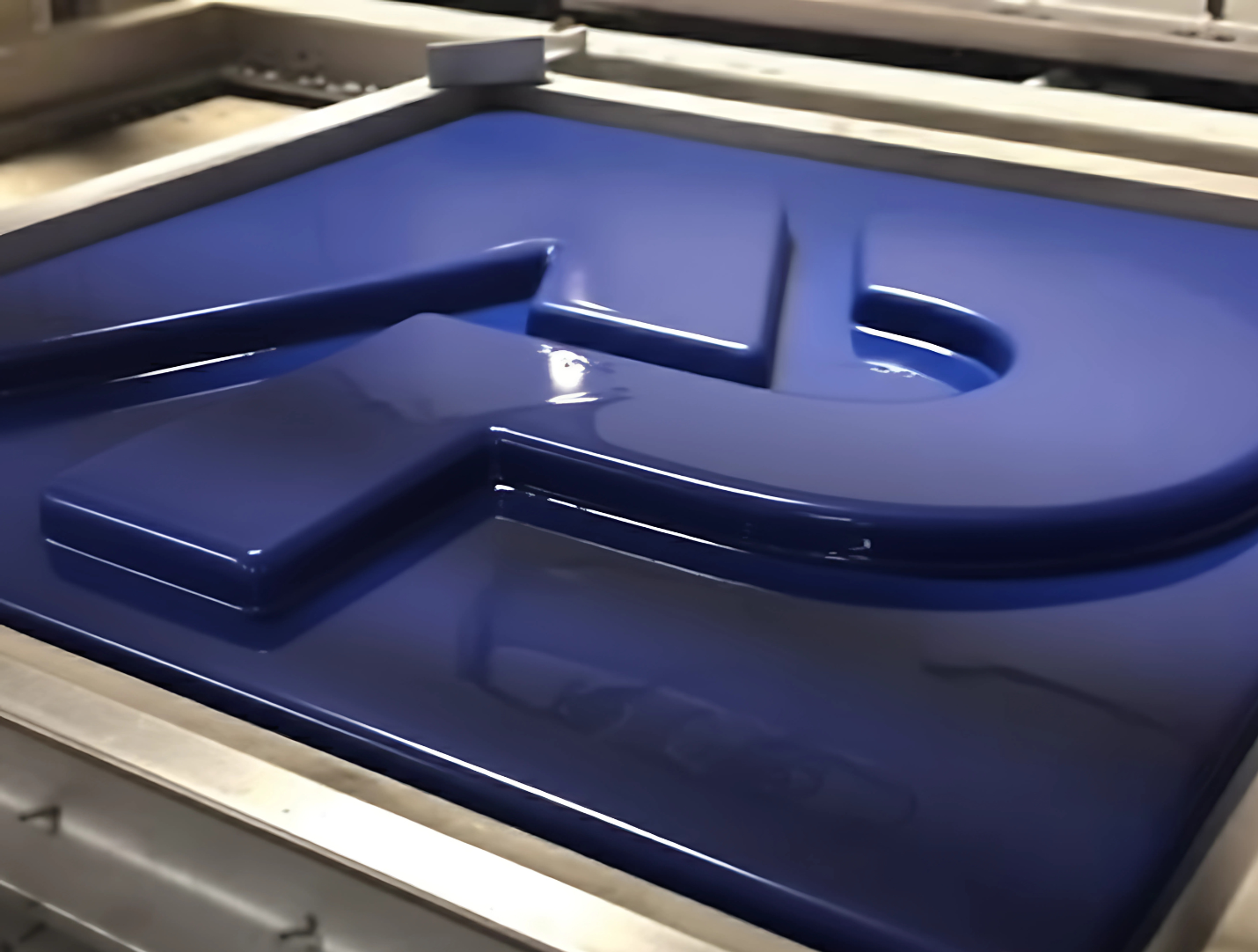

Signage

Our vast array of services includes signage solutions which can help your business stand out with creative 3D effects. Whatever your requirement, whether it be for a counter-top signage or for a building and billboard signage, we will work with you to design and manufacture a custom plastic sign to suit your needs.

Affordable, durable, and versatile, plastic signs can be indoors or outdoors. Call us to explore our variety of options.